Introduction to supply chain management

Feb. 17, 2024 • Reading time: 9 Min

Supply chain management is the smart organization of all the steps that are necessary for a company's supply chain to function optimally. From product manufacturing to transportation to customer satisfaction, supply chain management is critical to a company's success. Find out how modern supply chain management not only improves supply chain operations, but also contributes to the long-term success of the company and customer satisfaction. In this article, we would like to give you a rough introduction to supply chain management.

In brief: Supply chain management

Supply Chain Management (SCM) is crucial for the success of companies, as it efficiently organizes all steps of the supply chain, from raw material procurement to the delivery of finished products. The goal is to provide the right products at the right time and place to avoid bottlenecks, reduce costs, and maximize customer satisfaction. Effective inventory management and smooth logistics play a central role. By using modern information technologies, companies can improve their supply chain processes and use real-time information to respond more quickly to customer needs. Risk management is also important, enabling companies to identify and resolve potential problems early, minimizing disruptions. Sustainability is becoming increasingly significant, as environmentally friendly measures positively impact business success. The Supply Chain Due Diligence Act obliges large companies to make their supply chains human rights and environmentally friendly.

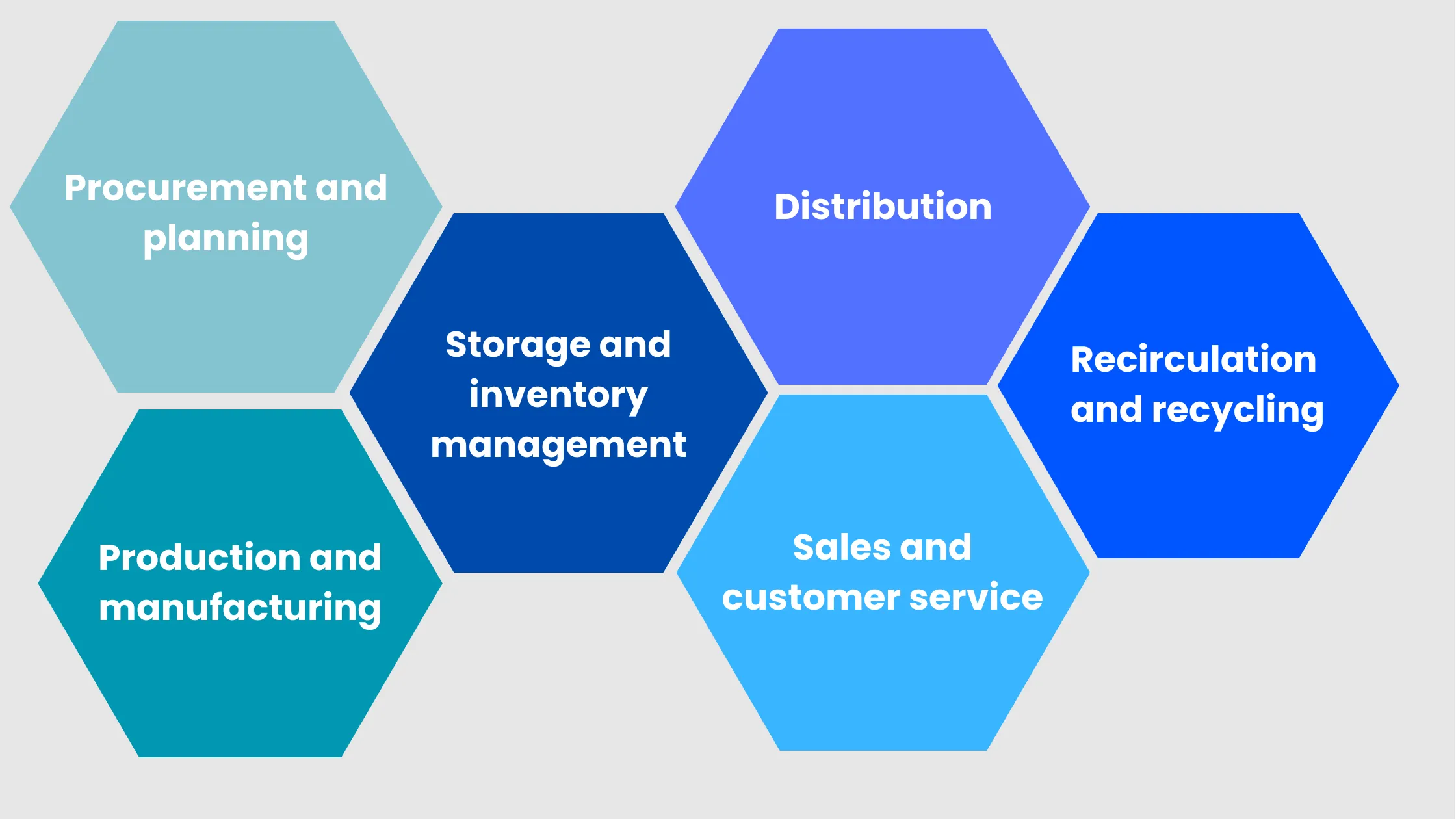

SCM encompasses six phases: procurement, production, storage, distribution, sales and customer service, and returns and recycling. Each phase contributes to the efficiency of the entire supply chain, with optimal inventory planning, effective use of storage space, and adherence to safety regulations being crucial. Transport and logistics must work seamlessly together to save costs and ensure customer satisfaction. Sustainable transport methods and the use of modern technologies contribute to efficiency and environmental friendliness. Information technology allows precise monitoring and control of the supply chain, increasing flexibility and responsiveness. Sustainable Supply Chain Management (SSCM) integrates environmental, social, and economic aspects into all phases of the supply chain, with measures to reduce greenhouse gases, adhere to labor standards, and promote long-term economic sustainability being central elements.

A sustainable supply chain can lead to cost savings and a better corporate image, as more consumers prefer environmentally friendly products. Overall, efficient and sustainable SCM is crucial for a company's success. It improves operations, increases customer satisfaction, and promotes business growth. Modern technologies and the just-in-time principle help minimize storage costs and maximize efficiency. Investments in the supply chain strengthen competitiveness and make a positive contribution to society and the environment.

Subscribe to never miss any insights.

Receive regular insights and updates on the latest developments in the areas of LkSG, CSDDD, CSRD, ESRS, compliance, ESG and whistleblowing. Our newsletter helps you to simplify your compliance processes.

Basics of supply chain management

Definition and objectives of SCM

Supply chain management (SCM), also known as supply chain management, is relevant for companies in order to organize all steps of the supply chain as efficiently as possible. SCM refers to all processes from the procurement of raw materials to production and shipping to customers. It also takes into account all parties involved, such as suppliers, manufacturers, logistics service providers and retailers.

The aim of supply chain management is to ensure that the right products are available in the right place at the right time. This avoids bottlenecks, reduces costs and maximizes customer satisfaction at the same time. Efficient warehouse management plays a crucial role here. It enables companies to organize and monitor the inventory of goods across the entire value chain.

Transportation and logistics are closely linked and complement each other. The two sectors are crucial for transporting goods quickly and efficiently to where they are needed. Companies can improve these processes and workflows by using information technologies and modern software solutions. They receive information about orders for their products in real time. This enables them to respond more quickly to customer needs.

Risk management is another important task in SCM. Companies must identify potential problems in their supply chain as early as possible in order to implement appropriate solutions. This can minimize disruptions and delays in the supply chain. Sustainable supply chain management is also becoming increasingly important, as environmentally friendly measures are having an ever greater impact on a company's success.

Companies that use well thought-out and efficient supply chain management can therefore benefit from a number of advantages: smooth shipping of goods, effective cost management and increased customer satisfaction are just a few examples. SCM should therefore be seen as an important and forward-looking task, because only by continuously looking for ways to improve their value chain can companies remain fit for the future.

Importance of supply chain management for companies

SCM is crucial for the success of companies. The main objectives of supply chain management are to improve competitiveness and reduce costs. Thanks to new logistics techniques and strategies, companies can shorten their delivery times in order to better meet the needs of their customers and remain competitive.

SCM also helps to make production more environmentally friendly. By choosing their suppliers wisely and planning their transportation routes carefully, companies can reduce their environmental impact. This aspect is particularly important for customers, who nowadays place greater value on environmentally friendly products.

An efficient supply chain also ensures that customers are supplied with high-quality products on time. This not only increases customer satisfaction and loyalty, but also promotes positive recommendations, which are of great importance to companies.

An efficient supply chain also ensures that customers are supplied with high-quality products on time. This not only increases customer satisfaction and loyalty, but also promotes positive recommendations, which are of great importance to companies.

Since January 1, 2024, companies with more than 1,000 employees must ensure by law that their supply chains are free from human rights violations and environmental damage. It is the duty of companies to take appropriate measures to minimize the risks and, at best, prevent them altogether. These requirements are enshrined in the Supply Chain Act. They stipulate which due diligence obligations the companies concerned must fulfill in order to protect human rights along the supply chain. Around 4,800 companies in Germany are currently subject to this law.

With effective supply chain management, companies can adapt more easily to market requirements and are therefore more successful in the long term.

The different phases of the supply chain

Supply chain management involves a series of important steps to ensure that everything runs smoothly in the supply chain and that customers are satisfied. The end-to-end processes of a supply chain consist of six phases. These are critical to a company's success in delivering products to customers.

Procurement and planning

In the initial phase of a supply chain, the focus is on procurement. Companies acquire the necessary raw materials, materials and components to manufacture their products. This process starts with the identification of the required materials and the determination of quantities and quality standards. In procurement planning, suppliers are then evaluated, prices and contract terms are negotiated and delivery deadlines are set. An effective and now also sustainable procurement strategy is crucial here. This is the only way to ensure that companies receive the materials they need on time and at competitive prices.

Production and manufacturing

Once the materials are available, production and manufacturing follow. This is where the various products are manufactured using the raw materials and components. Production and manufacturing consist of various steps such as assembly, production, processing, packaging and quality control. It is important that the individual production steps are carried out as efficiently as possible. This enables production targets to be achieved, product quality to be assured and costs to be controlled. The more efficient the production process, the better the overall performance of the supply chain. Technological advances such as automation, robotics and data analysis can optimize manufacturing processes and increase productivity.

Storage and inventory management

The third phase of a supply chain involves storage and inventory management. This is where the finished products are temporarily stored before they are shipped to customers or retailers. Warehouse management involves the storage, organization, tracking and control of stock. In particular, inventory control is crucial to ensure that products are available at the right time. Good inventory management is important for companies to reduce storage costs, avoid bottlenecks and improve delivery capability. Modern technologies such as warehouse management systems (WMS) and automated warehouse robotics can help to make warehouse operations more efficient and accurate.

Distribution

The distribution process is the process by which goods are transported from the warehouse or distribution center to the end consumer or retailer. This phase includes various logistical activities such as packaging, labeling, dispatch planning and transportation. The choice of means of transportation depends on the type of products, distance and time constraints. Common means of transportation are trucks, trains, ships and airplanes. Timely and reliable delivery of products to customers depends on efficient distribution. Delays or problems in this step can lead to customer dissatisfaction.

Sales and customer service

After the products have been delivered to the customers, the sales and customer service phase follows. In this phase, the products are sold and all associated transactions are processed. This includes sales via various distribution channels such as retail stores, e-commerce platforms or directly from the manufacturer. Customer service also plays an important role as it provides support for questions, problems or returns. Effective customer care can increase customer satisfaction and strengthen customer loyalty.

Recirculation and recycling

The final step along the value chain deals with the return and recycling of goods. This includes the repair or replacement of defective products, the return of unwanted goods or the recycling of packaging materials. Return and recycling measures are primarily used when companies want to conserve resources, reduce waste and comply with environmental regulations. From an environmental point of view, recycling can offer a number of advantages. It can even improve a company's image and strengthen customer loyalty.

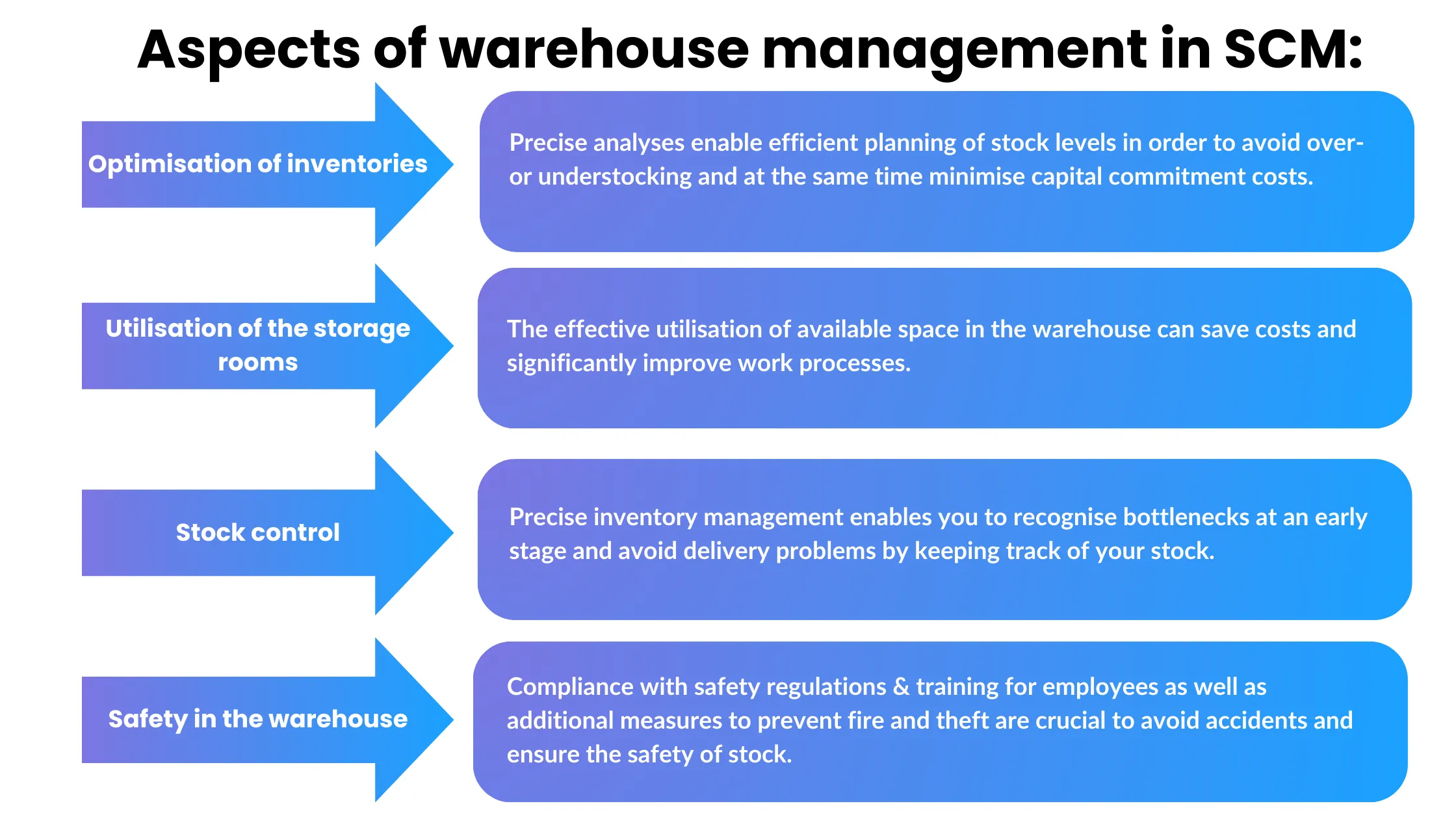

Important aspects of warehouse management in the supply chain

Warehouse management plays a crucial role and contributes to the smooth running of the entire supply chain. There are various factors that need to be considered to ensure the efficiency and effectiveness of the entire process.

Optimization of inventories

If companies analyze exactly how high the future demand for certain products will be, this allows them to plan their stock levels precisely. As a result, the warehouse is never overstocked or understocked. To ensure a smooth production process and keep costs as low as possible, prices are already taken into account during planning.

Use of the storage room

The effective use of available space also plays a decisive role in cost-efficient warehouse management. Clever use of the available space can save costs and significantly improve work processes. This can be achieved by cleverly arranging shelves, using lifting gear and other tools or introducing a smooth flow of goods in the warehouse.

Stock control

Accurate stock management is also crucial. It helps to detect bottlenecks at an early stage and avoid delivery problems. By regularly checking stock levels, companies can keep track of which items are in stock and which need to be reordered.

Safety in the warehouse

It is important to comply with clear safety regulations. Accidents can be avoided through regular employee training. Measures to prevent fires and theft also help to ensure safety in the warehouse.

A well-organized warehouse is crucial for a smooth supply chain. Companies can optimize their delivery processes by carefully planning their stock levels. They should use the available space efficiently and ensure security in the warehouse. In this way, smooth processes can be ensured.

Transportation and logistics as part of supply chain management

Smooth cooperation between transportation and logistics is of great importance for the management of a supply chain. This is the only way to guarantee an efficient process, save costs and ensure customer satisfaction. Effective coordination of production, storage and distribution of goods enables a fast and smooth process.

Logistics and supply chain managers are responsible for the organization and control of all transport and warehousing activities. They ensure that different means of transportation such as trucks, trains or planes work together smoothly and that goods are stored properly. They also make sure that the goods reach the customer on time. If problems arise, they are solved directly.

Sustainability in the supply chain is becoming increasingly important today. Companies are focusing more on environmentally friendly alternatives such as electric cars and renewable energies in order to act sustainably. In addition, modern technologies and computer programs are helping to optimize internal organization and ensure an accurate overview of the supply chain.

Risk management now also plays an important role in responding appropriately to unforeseen events such as natural disasters or political crises. Events such as these can affect transportation and the entire supply chain and, in the worst case, even completely disrupt it. Strong risk management prevents this.

Integration of information technology into the supply chain

Today, a company can no longer work without computers and various software. New technologies help to further increase efficiency in order to be even faster and more flexible. Companies can also use the latest technologies to optimize all processes in the supply chain and monitor and control everything from production to delivery.

A prime example of the integration of information technology into the supply chain is the use of warehouse management systems (WMS) or enterprise resource planning (ERP) systems. With these tools, companies can control their inventory, track orders and plan deliveries. In this way, products can be delivered to customers on time. At the same time, fewer difficulties and problems arise.

Modern IT tools enable companies to gain immediate insights into their supply chain. Using special devices such as sensors, they can closely monitor the location of their products, the environmental conditions and the condition of the goods. This information can prove useful when it comes to assessing supply chain performance and responding quickly to problems. The use of computers in the supply chain also helps to work in a more environmentally friendly way.

The use of IT tools brings further benefits: companies can reduce their energy consumption, cut their production of waste and find alternative transportation methods. According to a study, 94% of companies believe that such technologies help them to gain a better overview of their supply chain.

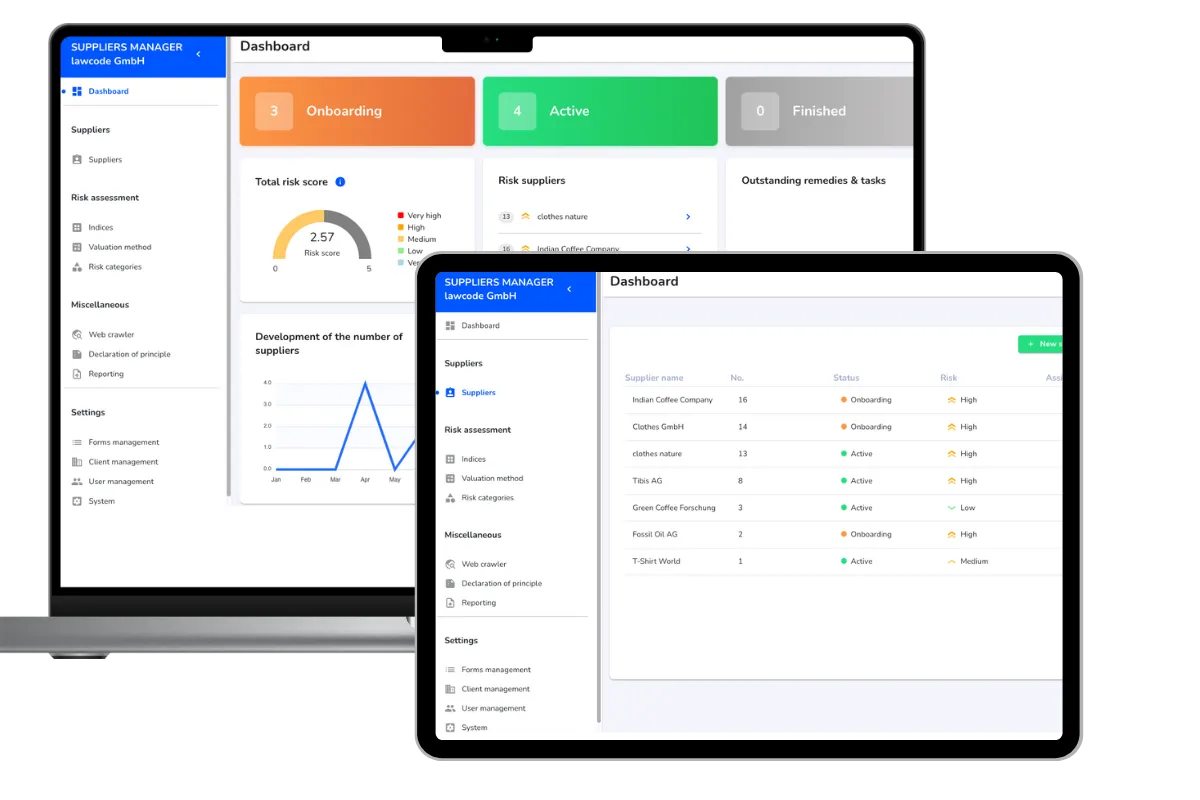

Supply chain management made easy

Supply chain management at a glance: Keep supplier management and risk management centralized in one place.

Systems and technologies that revolutionize your supply chain management

-

Enterprise Resource Planning of Supply Chain (ERP) refers to the integration of cross-business processes in an organization using a single software solution. In the context of supply chain management, ERP refers to how companies can efficiently use their resources such as materials, labor and financial resources to optimize the supply chain.

As part of SCM, ERP provides a central platform on which all relevant information about the supply chain can be collected, analyzed and managed. The ERP system can link different business areas such as procurement, production, warehousing, sales and finance. This enables companies to better plan their inventories, shorten delivery times, avoid bottlenecks and increase efficiency along the entire supply chain.

With ERP systems, companies can use real-time data to make decisions and react quickly to changes in demand or other external factors. By integrating ERP into SCM, companies can streamline their business processes, reduce costs and improve their competitiveness.

-

Warehouse Management Systems (WMS) are software solutions designed specifically for the efficient management of warehouses and distribution centers. They offer a range of functions, including inventory management, placement of goods, picking, packing, shipping and inventory management.

A WMS enables precise tracking of stock levels in real time. This leads to improved warehouse accuracy, reduced stock levels and efficient use of available warehouse space. By automating warehouse processes and integrating with other systems such as ERP and TMS, a WMS helps to optimize the entire chain and supply chain operations.

-

Transportation Management Systems (TMS) are software solutions that help companies plan, execute and monitor their transportation activities. A TMS offers functions such as route planning, freight cost optimization, shipment tracking, load consolidation and supplier management. By integrating real-time data on transportation capacity, freight rates and traffic conditions, a TMS enables efficient and cost-effective control of the transportation network. This leads to faster delivery times, lower transportation costs and improved customer satisfaction.

-

Supplier Relationship Management (SRM) encompasses the strategies, processes and technologies that companies use to manage and improve their relationships with suppliers. An SRM system enables companies to centralize supplier information, evaluate supplier performance, manage contracts, minimize supplier risks and identify collaboration opportunities. Through an effective supplier relationship, companies can improve the quality and reliability of their suppliers, reduce costs and promote innovation.

-

Demand planning software helps companies to forecast demand and orders. This enables them to optimize their inventory planning and avoid bottlenecks. This software analyzes historical sales data, market trends, seasonal patterns and other relevant factors to generate accurate demand forecasts.

By integrating with other systems such as ERP and WMS, the demand planning software enables seamless communication between the procurement, sales and production departments. This helps companies to have the right quantities of products in the right places at the right time. This is the only way to maximize customer satisfaction and optimize inventory levels.

-

Supply chain visibility tools provide companies with real-time insights into all aspects of their supply chain. This includes inventory movements, transportation status, supplier performance and customer demand. These tools use advanced technologies such as IoT sensors, RFID tags and big data analytics to collect, analyze and visualize data across the entire supply chain. By providing visibility and analytics, supply chain visibility tools help companies identify bottlenecks and issues early, minimize supply chain risks and improve responsiveness to changes in the market.

Risk management in SCM

Risk management in SCM is extremely important so that companies can manage their supply chains securely and efficiently. In today's networked world, companies are part of complex supply chains that extend from production to delivery to the customer. Various risks such as production stoppages, delivery delays or quality defects can occur time and again in supply chains.

Careful planning and close monitoring are required to avoid problems in the supply chain. Consideration should be given in advance to what difficulties could arise and how these can be resolved. It is important not to be dependent on just one supplier. By working with several different suppliers, the risk of disruptions and breakdowns can be minimized.

To manage risks in the supply chain, it is helpful to have access to computers and various software. This provides companies with up-to-date information about their supply chains so that they can react quickly to potential problems. If bottlenecks and delays are detected early, it is possible to react much faster and minimize the potential impact.

Sustainability is also becoming increasingly important when it comes to risk management in the supply chain. Companies that pay attention to environmental friendliness and fair working conditions tend to have fewer problems to contend with. Paying attention to sustainability has further advantages for companies: they become safer and at the same time more attractive to customers. Both have a positive effect on the company and are seen as a competitive advantage.

In supply chain management, it is important to minimize risks as they arise in order to ensure that everything runs smoothly. If computer programs and software systems are used sensibly for planning and monitoring, a company can reap many benefits. If sustainability aspects are also taken into account, this can have a positive impact on the company's image and success.

Sustainable Supply Chain Management (SSCM)

Sustainable supply chain management (SSCM) refers to the integration of environmental, social and economic aspects into all phases of the supply chain, including procurement, production, transportation, storage and disposal. The aim of SSCM is to minimize environmental impact, promote social responsibility and ensure long-term economic sustainability.

Factors of sustainable supply chain management

- Environmental protection: Environmental protection includes various measures such as reducing greenhouse gases, energy consumption, waste and pollution along the supply chain. To improve environmental protection, companies can, for example, switch to renewable energies, use more efficient means of transportation and introduce sustainable packaging solutions.

- Social responsibility: Social responsibility includes compliance with labor and human rights standards, fair working conditions, equal opportunities and respect for the rights of the communities in which companies operate. By promoting ethics and fairness in the supply chain, companies can achieve positive social impacts and strengthen stakeholder trust.

- Economic sustainability: Economic sustainability aims to ensure long-term value creation and competitiveness. This can be achieved by reducing risks, increasing efficiency and cutting costs. By making better use of resources, improving processes and workflows and promoting innovation, companies become economically stable in the long term.

Sustainability will play an increasingly important role, especially for companies that manufacture and supply products. Large corporations and multinational companies in particular must ensure that their operations are both environmentally and socially responsible. This means that they must pay attention to where and how their products are manufactured and how many emissions they produce in the process. One way to achieve this goal is to make supply routes and transport more efficient in order to minimize environmental impact - in line with sustainable supply chain management.

Switching to a sustainable supply chain not only offers environmental benefits, but can also lead to cost savings and improve the company's image. More and more customers prefer companies that are committed to environmental protection and social responsibility. 66% of consumers are even prepared to spend more money on sustainable products.

For sustainability to be successfully implemented in the supply chain, a holistic approach is required. This means that everyone involved in the supply chain - from manufacturers and suppliers to logistics companies - must work closely together.

Those who are responsible for management play a particularly important role. They ensure the cooperation of all parties involved and integrate sustainable practices into the supply chain processes. Supply chain managers or logistics managers must have the relevant know-how on how to make supply chains environmentally friendly and socially responsible. However, they must also undergo continuous further training in order to keep up to date with the latest legislation.

In order to comply with the legal responsibilities for a sustainable supply chain, companies are obliged to fulfill nine due diligence obligations in accordance with Section 3 of the Supply Chain Act(to the Act). It is therefore of great importance that companies consider sustainability to be a central component of their supply chain management and take appropriate measures.

Effective and efficient SCM

An efficient supply chain is crucial to a company's success. It helps to improve operations, satisfy customers and promote business growth. A well-organized supply chain enables a company to use its resources intelligently, reduce costs, deliver products faster and adapt flexibly to new challenges. The cost-benefit factor is a key aspect here, as an optimized supply chain is not only more efficient but also more cost-effective, which has a positive impact on the company's overall performance.

Modern supply chains rely on innovative technologies to maintain an overview of information and cash flows and ensure smooth collaboration. This allows problems to be identified at an early stage and avoided immediately. Supply chain management is therefore an important management task that requires strategic planning and continuous monitoring. A key element of this is the just-in-time principle, which ensures that materials and products are delivered exactly when they are needed in order to minimize storage costs and maximize efficiency.

Nowadays, sustainability is becoming increasingly important, as customers prefer environmentally friendly and fairly manufactured products. Companies that invest in and continuously improve their supply chains are not only more successful economically, but also make a contribution to society and long-term sustainability.

Overall, it is clear that a well-organized and sustainable supply chain is a decisive factor for the long-term success of a company. By investing in the supply chain, companies can not only strengthen their competitiveness, but also make a positive contribution to the environment and society.